Features

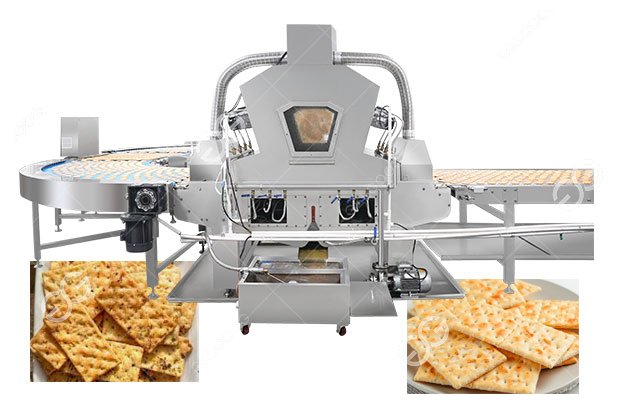

The automatic saltine crackers production line is becoming increasingly popular among food manufacturers. It is designed to handle large-scale saltine crackers production with high efficiency and minimal labor.

As the biscuit market grows, automation has become a key driver in enhancing productivity and maintaining high standards, making it a preferred choice for modern manufacturers. Automated systems increase efficiency, reduce labor costs, and ensure consistent product quality.

Features of Automatic Saltine Crackers Production Line

- The core equipment of this production line includes dough mixer, forming device, multi-temperature zone tunnel oven and cooling conveying system to ensure the best quality of biscuits.

- The production line is constructed from food-grade 304 stainless steel, ensuring compliance with international food safety standards. It is corrosion-resistant and easy to clean.

- Its compact design and small footprint make it suitable for a variety of food processing plants and baking companies.

- The production line is also equipped with a waste recycling system to effectively reduce waste and reduce production costs.

Diversification And Flexibility

In addition to salt biscuits, the production line can also produce a variety of products such as soda biscuits and sandwich biscuits through simple adjustments to meet different market needs. At the same time, the production line can also be equipped with additional functions such as egg liquid spraying, salt and sugar sprinkling to further enrich the product taste.

Market Advantages

The production line's production capacity meets large-scale market demands, making it ideal for food processing companies, baking factories, and chain brands. Automated control enhances efficiency and ensures consistent product quality, while reduced manual intervention lowers labor costs, delivering significant economic benefits.

Production Process of Saltine Crackers

After-sales Service

The equipment supplier provides comprehensive after-sales service, including installation and commissioning, operation training and technical support, to ensure that customers can quickly put into production and operate stably. Some suppliers also provide free recipe guidance to help customers optimize products.

This automatic saltine crackers production line has become a popular choice in the food processing industry with its high efficiency, intelligence and flexibility. It can not only help companies improve production efficiency, but also stand out in the fiercely competitive market and achieve sustainable development.

Technical Data

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method |

Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Leave Message

Related Machine