Features

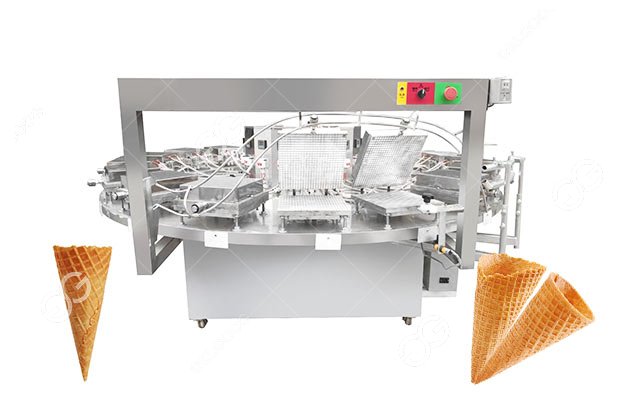

The ice cream biscuit cone machine has different models, can be used for the molding of ice cream biscuit cones. There are various types can be made, and it supports custom-made special sizes.

This machine is widely used, usually in ice cream factories, cone factories, and some ice cream shops(We have many models, will recommend suitable equipment according to the different sizes of customers).

How to Operate Ice Cream Biscuit Cone Machine

- Adjust the temperature: According to the instructions, adjust the temperature control knob to the recommended baking temperature. This temperature should be suitable for baking the biscuit sheets to ensure that the sheet can be evenly baked and not burned.

- Preheat the mold: Before starting to make, let the machine preheat to the set temperature to ensure that the biscuit sheet can start baking immediately after being placed.

- Pour the batter: When the mold reaches the appropriate temperature, open the baking tray, and the grouting machine will evenly pour the pre-prepared crispy tube batter into each baking tray.

- Bake the biscuit sheet: Close the baking tray and let the batter bake on the baking tray. During the baking process, the batter will gradually take shape and turn into golden biscuit sheets.

- Check the baking: After the baking time is over, check whether the biscuit sheet have been baked to the ideal color and hardness. If necessary, you can adjust the baking time appropriately.

- Open the mold: After baking is completed, the mold of the biscuit cone making machine automatically opens, and the biscuit sheet in the mold should be completely baked at this time.

- Roll the biscuit sheet: Use a dedicated ice cream biscuit cone rolling machine to quickly roll the hot biscuit sheet into a cone shape. This step needs to be completed before the biscuit sheet cool and harden to ensure the shape of the crispy biscuit cone.

- Finished product collection: Once the ice cream biscuit cones are completely cooled, they can be collected and used to hold ice cream or other desserts.

- Cleaning and maintenance: After each use, remember to clean the molds and machines to keep the equipment hygienic and extend its service life.

Features of Ice Cream Biscuit Cone Making Machine

- The equipment developed and manufactured in our factory is user-friendly and very easy to use.

- Whole equipment uses food grade materials, ensuring safer and more hygienic ice cream biscuit cones production.

- The complete set of equipment is mainly divided into beating, storage, baking and rolling parts and can be purchased separately.

- Different molds for different size and shape of ice cream biscuit cones, and you can replace the molds on the machine.

- The material of the mold can be changed according to needs, and can be customized for special needs.

Advantages of Ice Cream Biscuit Cone Machine

- Simple operation and easy to use. The equipment has a simple structure and is easy to use. Delicious ice cream biscuit cones can be made with simple operations. Even people without professional skills can quickly master the production skills.

- high productivity. We have developed different models of equipment for industrial use. It can make batches of ice cream biscuit cones in just a few minutes.

- Safe to operate and healthy material. The machine is made of high-quality stainless steel and has been specially treated to make it non-toxic, harmless, healthy and safe.

Technical Data

| Model | Capacity(PCS/H) | Power(KW) | Biscuit Size(CM) | Biscuit Thickness(MM) | Dimension(MM) | Weight(KG) |

| GGDCD-6 | 300 | 10 | 7-20 | 0.5-4 | 1400*1400*1250 | 250 |

| GGDCD-9 | 400-600 | 14.5 | 7-20 | 0.5-4 | 1600*1600*1250 | 270 |

| GGDCD-12 | 600-800 | 19 | 7-20 | 0.5-4 | 1700*1700*1250 | 300 |

| GGDCD-15 | 800-1000 | 23 | 7-20 | 0.5-4 | 1800*1800*1250 | 330 |

| GGDCD-18 | 1000-1200 | 28 | 7-20 | 0.5-4 | 1900*1900*1250 | 360 |

Leave Message

Related Machine